Bonding

Assemblies

II-VI Optical Systems' Assembly area is equipped with all levels of NIR & IR optical assemblies. The Assembly group has experience in opto-mechanical, and various opto-electronic assemblies ranging from simple to complex configurations. II-VI Optical Systems can build assemblies to print, refine a current optical design to a provide a more cost effective / manufacturable solution, or design an assembly based on a Statement of Work (SOW). The Assembly team utilizes class 1,000 / class 10,000 clean room space and is geared toward defense based industries.

Bonding / Assembly Techniques

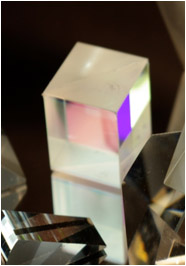

II-VI Optical Systems performs various types of optical bonds on various types of materials. II-VI Optical Systems is proficient in optical contacting, UV cure bonds, various adhesives, and chemically activated bonds just to name a few of the techniques.

II-VI Optical Systems has a chemically activated bond process called the V-LOCK Bonding process. This process is superior to other processes with its ability to bond similar and multiple dissimilar materials together (something other processes don’t offer).

Products

II-VI Optical Systems will utilize the appropriate techniques depending on your application. Below are some examples of types of bonded assemblies II-VI Optical Systems provides routinely.

Product Experience:

- Opto/mech Assemblies

- Electro/optical sub

- Window Assemblies

- Null Lens Assemblies

- Doublets, Triplets

- Eye piece Assemblies

- Mirror mount Wedge Assemblies

- Rifle Scopes

- Prism Assemblies

- Assemblies Binocular Assemblies

- Reflector Assemblies

- Led Assemblies

- Aspherical lens Assemblies

- Beam Combiners

- Reticle Assemblies